Research & Development The strongest company in the production of customizing valve and the technology innovation for building the power generation facility!

Select Language

주메뉴

Company

The Strong Of Technical Renovation

현재메뉴

1. Localization of BFPT HP STOP Valve Disc & Stem Ass’y in standard thermal power plant (May 2013)

Intended use

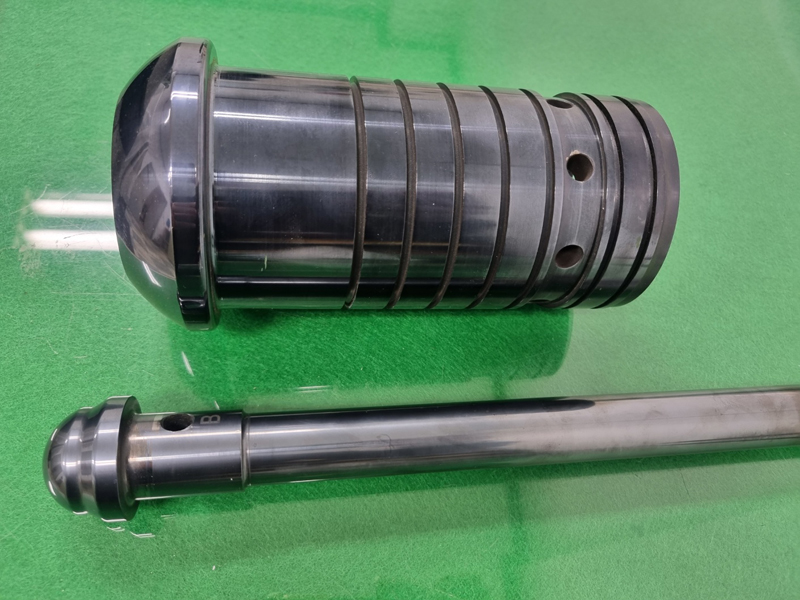

- BFPT HP STOP Valve is Poppet Type, composed of Pilot Valve and Outer Valve.

- It is a valve turning ON/OFF the main steam system provided by using drive turbine of water pump.

Development Content

- Disc Gland → Installation of air chamber function

- Main Disc → Structure change (airtightness and anti-rotation of stem)

- Pilot Disc & Stem → Installation of back seat section and feature of air chamber

Applications

- All power plants equipped with BFPT HP STOP VALVE

2. Development of deteriorated scale non-seated valve trim (July 2013)

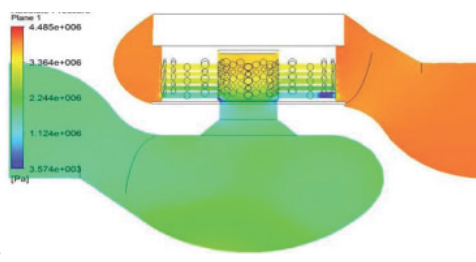

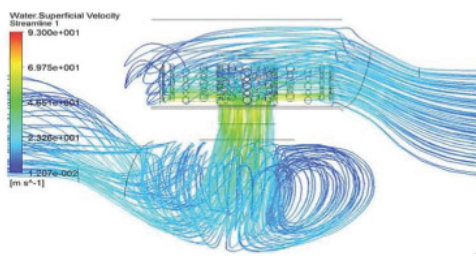

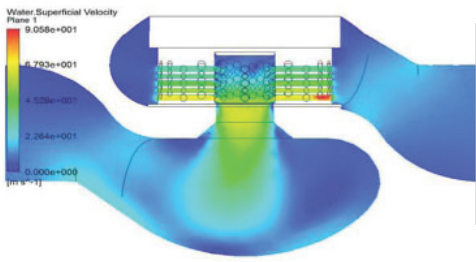

Outline

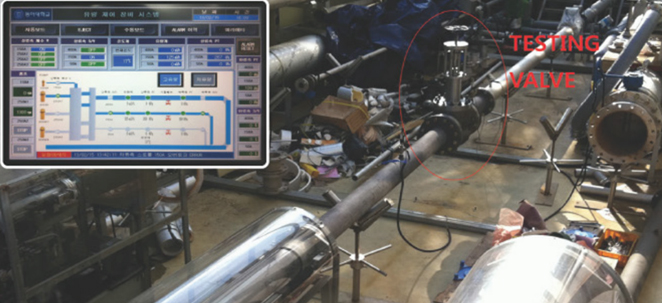

For the valve trim controlling a fluid (Plug, Ball, Seating, Cage, Stem), durability to withstand the harsh condition of the system is important. For this, properties of low friction coefficient, high wear-resistance, hear-resistance and corrosion-resistance can be given to the product by depositing coating material (e.g. a-C:H, Al, Ti, TiW, W, TiN, Pt) using physical vapor deposition (PVD) on the surface of product made after selection of material, configuration design and flow analysis. This enables to extend the service life of valve and valve trim and ensures the reliability and safety of power generation facilities.

Purpose

- Valve trims by prohibiting scale attachment

- Enhancement of durability of valve trims

- Enhancement of corrosion and heat-resistance of valve trims

- Derating of valve relative motion parts

Test & Inspection

[Flow analysis]

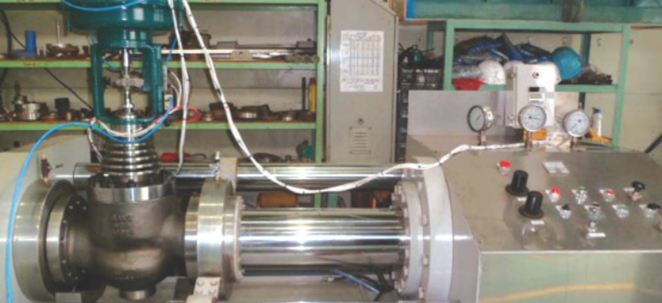

[Durability tests of 100,000 times]

[Durability tests of 100,000 times] [Wear condition after durability test]

[Wear condition after durability test] [test of scale seat]

[test of scale seat] [Cv test]

[Cv test]

3. Localization of Standard thermal power TBN Ventilator valve Disc Ass’y (March 2018)

How it works

The Ventilator Valve in Samcheonpo thermal power plant #1~4 is designed to close when air is supplied and to open when air is lost, but Valve Main Disc is closed being pressed by Pilot Valve embedded in the top.

Problems

- Entirely depends upon imports/high cost/prolonged procurement period of material (a few months)

- Leakage occurs frequently because the scale with high temperature and high heat is seated on Main Disc.

Solutions

- Life extension and performance improvement by structure change and grafting the performance certification and the patented coating technology held by SEO-HEAUNG MCO

- Maximization of durability of equipment and stability of operation

- Costs cut down through localization (70% or less)/Relieving the prolonged stock by shortening the procurement period of materials

4. Improvement of performance of feed pump of bio heavy oil in Jeju thermal power plant (June 2019)

Outline

Pump is worn within 3 months in average service life due to use of Bio palm oil/Reduction of equipment service life according to frequent replacement (4 times a year)/Occurrence of unplanned loss

Development content

- Applying the performance certification technique (P.V.D COATING)

- Applying to SCREW and INNER CASING

- Extending the cycle of damage (wear) by 2~3 times

- Zeroising the unplanned loss

5. Localization of overhauled low-torque type high temperature & high-pressure metal ball valve (November 2021)

Features

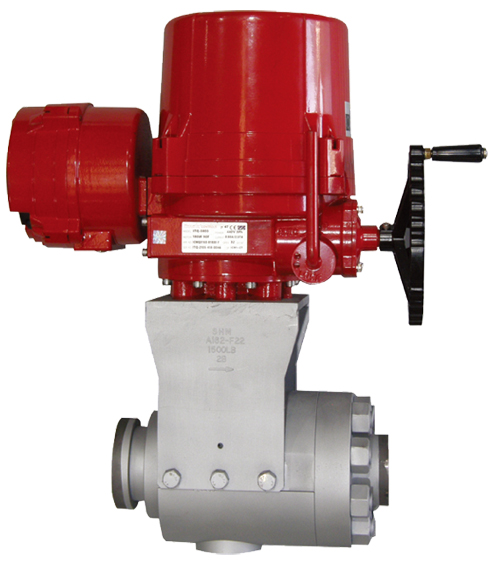

- Metal-Seal Ball Valve designed based on ANSI/ASME Class 4500 has the outstanding properties and advantages for the high pressure & high temperature (300kg/㎠ @ 700℃) fluid by grafting the nano coating/PVD.

- The service life of valve is extended even under harsh operation condition since LT-Ball Valve has the trunnion structure supporting the ball central axis with low torque and nano-coating/PVD on the operating part.

- High performance LT-Metal Ball Valve improved “out of commission, Trim sticking, high-Torque, leakage, life shortening, etc.” which are the shortcomings of Floating Metal Ball Valve.

- Zeroising the unplanned loss