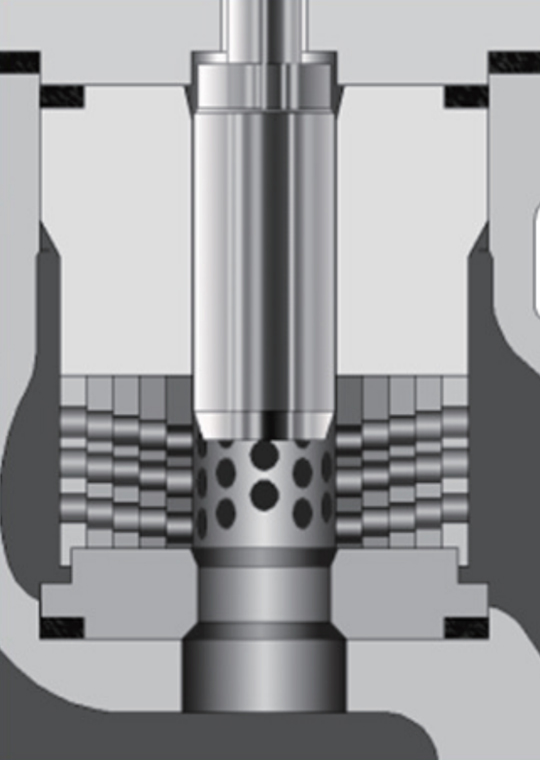

Top entry overhaul type metal ball valve with valve grade 4500 or less Top Entry LT. Metal Ball Valve

The Strong Of Technical Renovation

Top entry overhaul type metal ball valve with valve grade 4500 or less Top Entry LT. Metal Ball Valve

HP DRN, MS DRN, CBD, IBD, DRN system

| PART NAME | MATERIALS |

|---|---|

| BODY | A105, A182-F22, A182-F91, Alloy Steel |

| BALL | Cr. Alloy Steel + P.V.D |

| STEM | Cr. Alloy Steel + P.V.D |

| SEAT RING | Cr. Alloy Steel + P.V.D |

| PACKING | Graphite |

| P.S. GASKET | Graphite |

| SEAT SPRING | Inconel |

| PART NAME | SPECIFICATIONS |

|---|---|

| VALVE SIZE | 1″ ~ 4″ |

| APPLICABLE RATING | ASME CLASS 150 ~ 4500 |

| CODE & STANDARD | API, ASME, ASTM |

| Main Steam | 300㎏/㎠ @ 570℃ |

| LT | Low Torque |

[Existing valve replacement complete]

[Existing valve replacement complete] [Remove the bonnet after 3 months]

[Remove the bonnet after 3 months] [Remove seat housing]

[Remove seat housing] [Remove the Ball Seatring]

[Remove the Ball Seatring] [Remove the seal retaining ring]

[Remove the seal retaining ring] [Disassembly completed, dedicated tool]

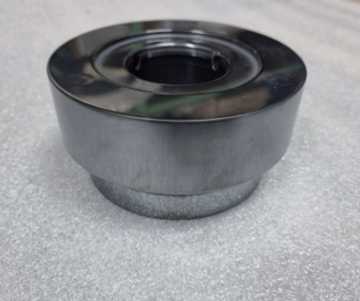

[Disassembly completed, dedicated tool]Valve trim with improved durability by shock absorbing layer Valve Trims by Prohibiting Scale Attachment and Improving Durability

Manufacturing technique extending the life of valve applied to harsh condition of high temperature & high pressure fluid

Assembly

Assembly

Plug stem

Plug stem Seatring

Seatring Cage

Cage Guide

Guide